'Made in England' - what you can learn from a pottery backstamp

This story covers the production of the 'Made in England' backstamp mosaic in the Potteries Museum and the information which can be found from such backstamps.

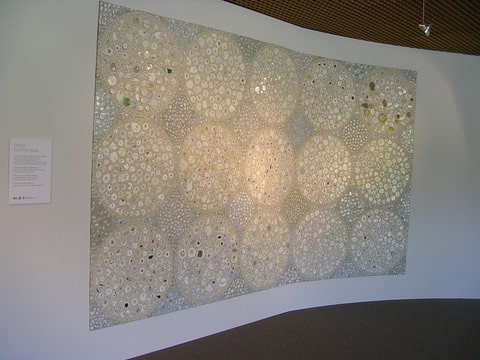

This is the 'Made in England' mosaic which is in the foyer of the Potteries Museum in Hanley, Stoke-on-Trent.

The mosaic was made by Emma Biggs as a homage to the ceramic history of 'The Potteries' and was installed in April 2007

http://www.myalbum.co.uk/Photo-J3337Q7K-D.jpg

The 'Made in England' mosaic was commissioned to commemorate the glorious history of the ceramic history in the Potteries.

Many of us who live in the area automatically turn over a piece of pottery we can't immediately identify to look at the backstamp on its underside.

I was lucky enough to be able to work with Emma Biggs during the collection of the backstamps from plates donated by local people and I offered to write an article on what information can be found out from backstamps for the project Internet site.

http://www.myalbum.co.uk/Photo-FQKGNKLN-D.jpg

Following an appeal in the local newspaper and on local radio, many residents of Stoke-on-Trent donated plates from which the backstamps were carefully removed.

At the same time stories about the donors and their memories of working 'in the pots' were recorded and these have been posted online.

Emma Biggs then organised the whole collection of backstamp fragments into a set of colour grouped roundels and other shapes which make up the Made in England mosaic.

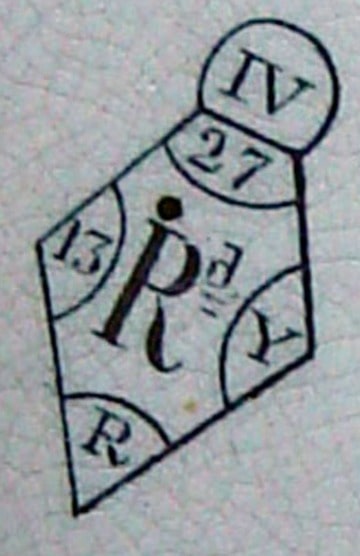

A backstamp selected at random from the thousands used to create the 'Made in Ebgland' mosiac.

http://www.myalbum.co.uk/Photo-XUXZGVTH-D.jpg

Many people born in the ‘Potteries’, as the City of Stoke-on-Trent is often known, have a history of family members working in the industry. To us, it is second nature to turn over a piece of pottery of a type or pattern we haven't seen before to look at the backstamp.

It often surprises visitors to discover just how much information you can find by looking at a backstamp, with a little help from a standard reference book. As an example, please see the details below for a backstamp randomly selected from those used for the Made in England mosaic.

Maker:

The maker' s mark is B. G. & W.

Geoffrey Godden's ‘Encyclopaedia of British Pottery and Porcelain Marks’ is probably the most useful reference book with which to research your backstamp: any UK reference library should have a copy.

Godden tells us that the abbreviation above stands for Bates, Gildea & Walker. The company operated the Dale Hall Works in Burslem between 1878 and 1881, making earthenware and china. It was formerly Bates, Walker & Co and subsequently became Gildea & Walker.

As this factory only operated for three years under the Bates, Gildea & Walker name, we are able to date the ware with great accuracy.

Please note, however, that many longer-lived factories changed their marks over the years. It is often possible to place a piece within a limited period by comparing the mark with the examples in Godden.

Occasionally a mark may not be found in Godden or its origin may seem uncertain. Unfortunately, there are many small or short-lived factories for which no data is available. In such a case, keep looking in every reference book you can find and try posting a query on one of the antiques news-groups.

Pattern name:

Godden notes that the pattern name was often used alongside the mark. In this case we can be reasonably sure the pattern name was ‘Satsuma’. This fits the date, as there was a Victorian vogue for Japanese style at the time.

Registration mark:

The diamond-shape is a Victorian registration mark. This system was used from 1842 - 1881 as a means of protecting a particular pattern (or shape of ware) from piracy for a three-year period. The system could also be used by foreign manufacturers, so the presence of a lozenge does not guarantee a British origin.

The Victorian design registration diamond next to the backstamp.

http://www.myalbum.co.uk/Photo-U7CHUBBK-D.jpg

Two types of diamond were in operation, which makes a reference book essential in order to decipher the code. This is a ‘right-hand’diamond, telling us the pattern was registered on 27th August 1879, and confirming the factory date.

In 1884 a simpler system came into use. It is based on numbers, and it is still in use today. Godden gives a short table of first numbers for a range of years: for precise information it is necessary to consult the registration details in the archives of the Patent Office.

http://www.myalbum.co.uk/Photo-CKBWJUNL-D.jpg

Other marks and indications:

Here, you can see the impressed mark ‘7/80’. The most likely interpretation of these numbers is that the piece was produced in the raw state in July 1880. If pottery is kept in store for long periods between firings it can absorb moisture from the atmosphere, which may cause faults in later firings. For this reason it was useful for the factory to know when the ware was produced.

Sometimes, numbers and letters may be painted on, or impressed into the ware. In some cases, they may refer to the shape of the ware or indicate a pattern number. In others, they could be an individual worker' s mark used to ensure they were paid for the work they had done.

Impressed marks have to be made while the body is still soft - before the ware has been fired at all. This means they usually don't refer to a pattern, as the same ware might have any of a number of designs applied later.

The word ‘England’ normally indicates a date after 1891. ‘Made in England’ indicates a 20th century date. The country of manufacture was included after an American law was introduced requiring imported goods to be so marked.

No marks:

Many small factories would not have marked their products for the home market: they might also have been producing whiteware to be sold to other manufacturers for decoration. In such a case, the ware would obviously bear the final manufacturer' s marks.

Impressed marks:

These can often be difficult to read. Try illuminating the piece from the side or make a tracing with a soft pencil. If this is still unclear, transfer the tracing to a graphics package on a computer and use an ‘edge-enhance’ filter to sharpen up the edges.

Crazing:

Another characteristic of this piece of ware is that the glaze is crazed. The glaze is actually a thin layer of glass: this is strong under compression, but weak under tension. If the thermal expansions of the body of the ware and of the glaze are not correct, the glaze layer is under tension once it cools, rather than under compression. If this happens, it will, sooner or later, craze.