Ceramic insulators - forgotten products of the pottery industry

Everyone knows pottery - vases, tableware, tiles and toilets just for example.

There are several important branches of ceramics which are often forgotten - bricks for example - however, ceramic insulators played a vital role in the development of high-voltage electrical equipment, the 'National Grid' electricity distribution network and the electric telegraph.

Coming from Stoke-on-Trent, the home of the UK ceramics industry, I was reminded of this both while looking at the Science Museum's reserve 'small-item' store in Blythe House and also in the public displays at the museum in Exhibition Road, London.

http://www.myalbum.co.uk/Photo-YOZCH8F3-D.jpg

Browsing part of the Wellcome collection in Blythe House showed a number of pieces of equipment where ceramic insulators were clearly visible : high-voltage X-ray generators and radio transmitter components.

With a normal piece of pottery it's generally possible to find information about a piece by turning it upside-down and looking at the backstamp. This wasn't possible with any of these components as they were built-into the equipment, but it's very likely that most of them had been manufactured in Stoke-on-Trent.

Ceramic insulators can be clearly seen in the original BBC '2LO' radio transmitter which involved use of voltages up to 22500 V. It came into service in May 1922.

http://www.myalbum.co.uk/Photo-AH4FYA67-D.jpg

A telegraph pole complete with a set of ceramic insulators.

http://www.myalbum.co.uk/Photo-AMF6BJ8N-D.jpg

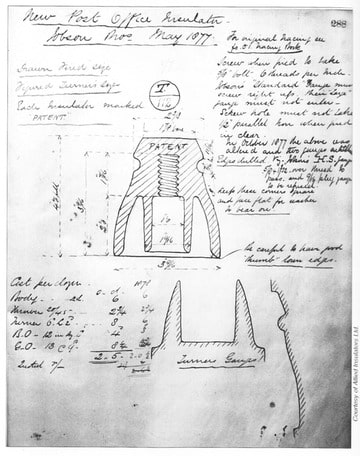

An 1877 design by Bullers for a new type of telegraph insulator for the Post Office.

http://www.myalbum.co.uk/Photo-ATJSNNUK-D.jpg

One of the most important manufacturers of ceramic insulators was Bullers.

Based in Milton, Stoke-on-Trent, this company manufactured both small insulators for scientific equipment, radio transmitters, electric trams and the London underground and telegraph equipment and huge insulators used in the developing UK electrical distribution network and which were always seen hanging from pylons.

Other companies amalgamated with Bullers to form the Allied Insulators group.

This is a view of Bullers Hanley factory in ca. 1925 - 30 showing once-fired (biscuitware) insulators being dipped a glaze mixture (left) or being aerographed (sprayed) with glaze (right).

After thorough drying, the insulators would then have their second (glost) firing.

http://www.myalbum.co.uk/Photo-T66N7TMB-D.jpg

The Bullers group also had a factory Hanley, Stoke-on-Trent and this photo shows women in the fettling shop in about 1908.

'Fettling' is the term used for the job of cleaning up not-yet-fired ceramics by removing seams and other blemishes using a sharp knife.

http://www.myalbum.co.uk/Photo-LCJKC837-D.jpg

A set of large ceramic insulators - probably manufactured by Bullers - on display at Gladstone Pottery Museum, Longton, Stoke-on-Trent.

http://www.myalbum.co.uk/Photo-6GGLFGZY-D.jpg

I'm not aware of any old film footage showing insulator manufacture in the UK, but this shows the process in America about 1920.

https://www.youtube.com/watch?v=wenzDpwA9xA

The former Bullers factory in Hanley : now a residential complex.

There aren't many people living in a building containing a real bottle-oven !

http://www.myalbum.co.uk/Photo-Z87NKOZS-D.jpg

Bullers later history

Bullers later became part of the Allied Insulators group but later both of their factories in Milton and Hanley closed.

Nothing remains of the Milton site, but the remaining part of the Hanley factory - including its bottle-oven - was renovated and is now a residential complex.

More information about this at :- http://www.thepotteries.org/listed/60a.html